Labelling machines

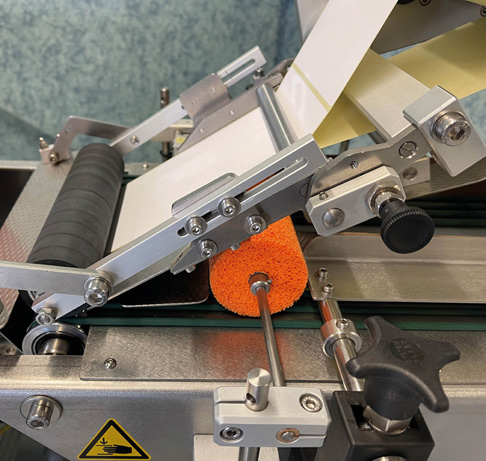

Our labelling machines can be installed flexibly and adapt to different conveyor speeds and attachment situations. When installed in a conveyor system, they ensure extremely high labelling accuracy – cleanly and precisely.

Depending on your requirements, the labelling machines can process labels of different widths: you can choose from the models SES 80, SES 120, SES 160, SES 200 and SES 250.

In addition to the standard sizes, special sizes of up to 320 mm are also available on request.

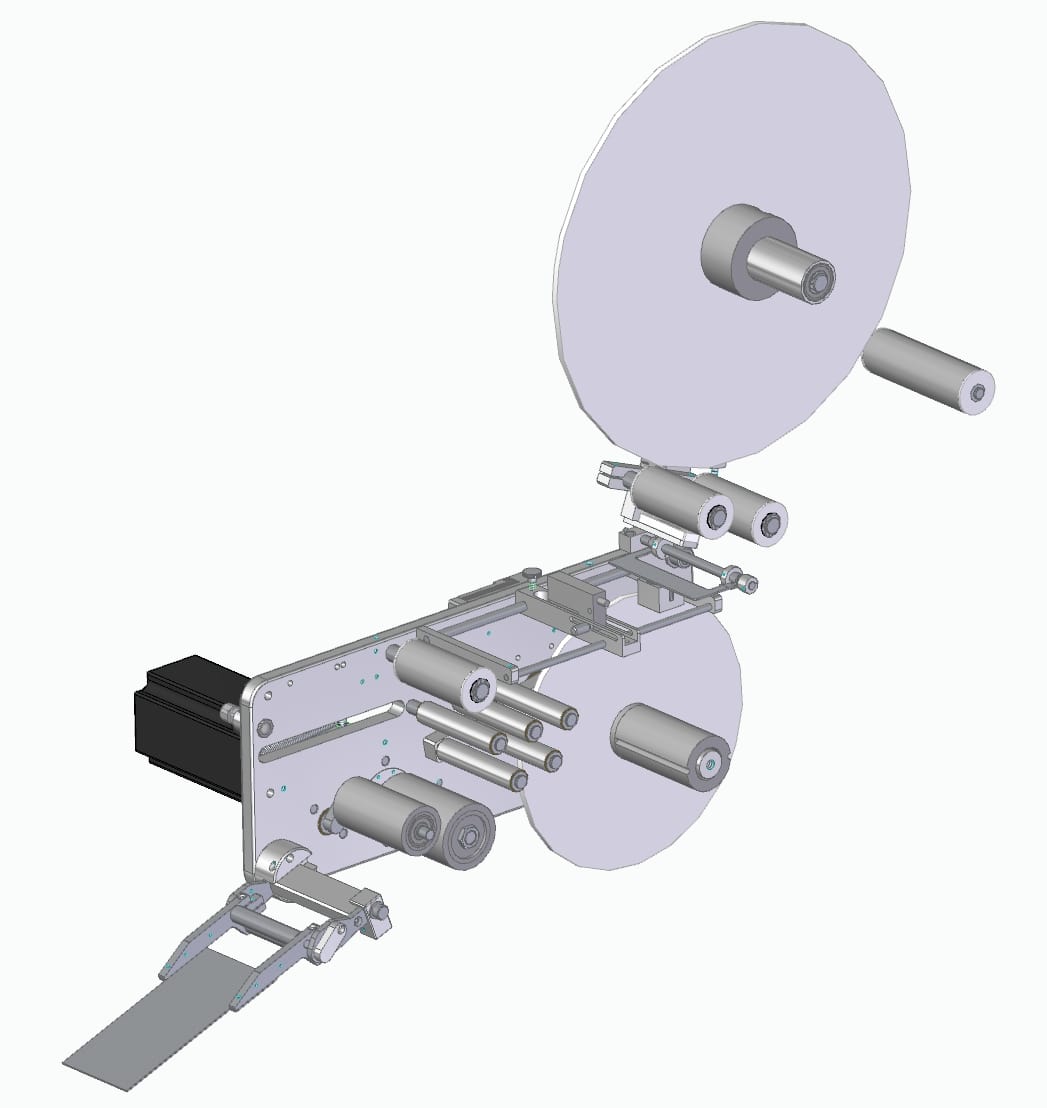

Fully automatic labelling machines –

our labelling machines for installation

Our fully automatic labelling machine for installation can be integrated into any conveyor system and is available for many different packaging lines, in different versions, with different components and for a wide range of products to be packaged – for example for: tubular bags, cardboard boxes, blisters, films, bottles, pallets, trays or crates.

Fully automatic labelling machines work efficiently and adapt individually to your production line or packaging machine. They take over the complete labelling process.

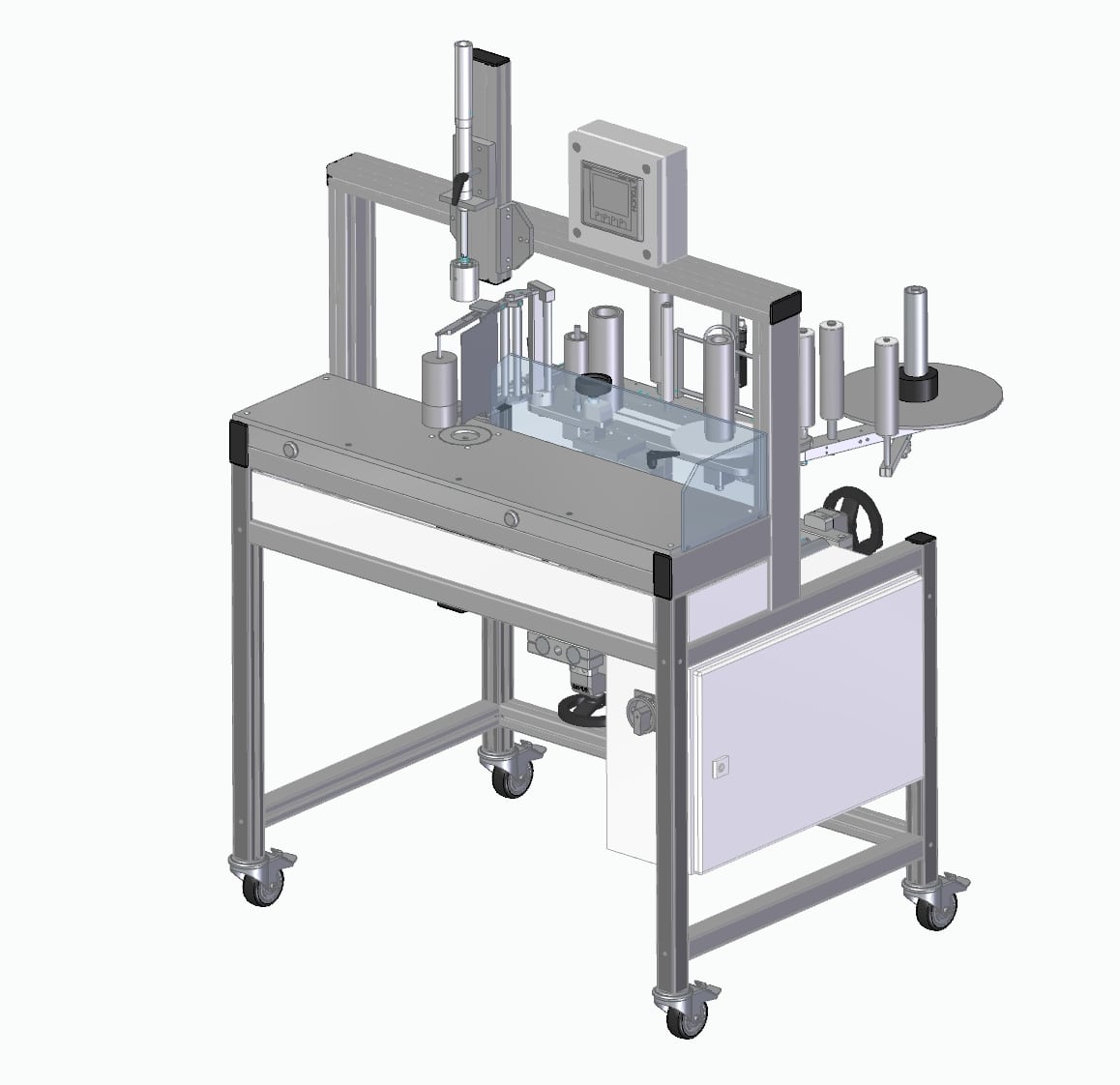

Semi-automatic labelling machines –

ideal for seasonal runs

They are perfect for shorter runs or complex product shapes such as round, oval or square packages made of a wide variety of materials, or even complex containers with free-form surfaces. They are flexible, compact and handy: our semi-automatic labelling machines. Simple manual operation and fast, accurate labelling are further plus points. Up to 1,000 products per hour can be labelled with this efficient machine. These include, for example, wine bottles, cans, glasses, bags, cardboard boxes, tubes and books. Special formats such as syringes, cartridges etc., are also possible.

You simply insert the product – the semi-automatic labelling machine takes care of accurate, clean labelling. Single or double-sided labelling, label dispensers for different label sizes and widths, and devices for any product shape also make your labelling process time and cost-efficient.