Quality and innovation meet customised solutions: our machines

From individual labelling machines to complete labelling systems – we supply you with the right solution. Whether it’s an existing machine that needs adaptation or a new design: we have a wide range of robust and durable labelling solutions, from standard designs to special machines and special solutions, and can draw on a wealth of accessories.

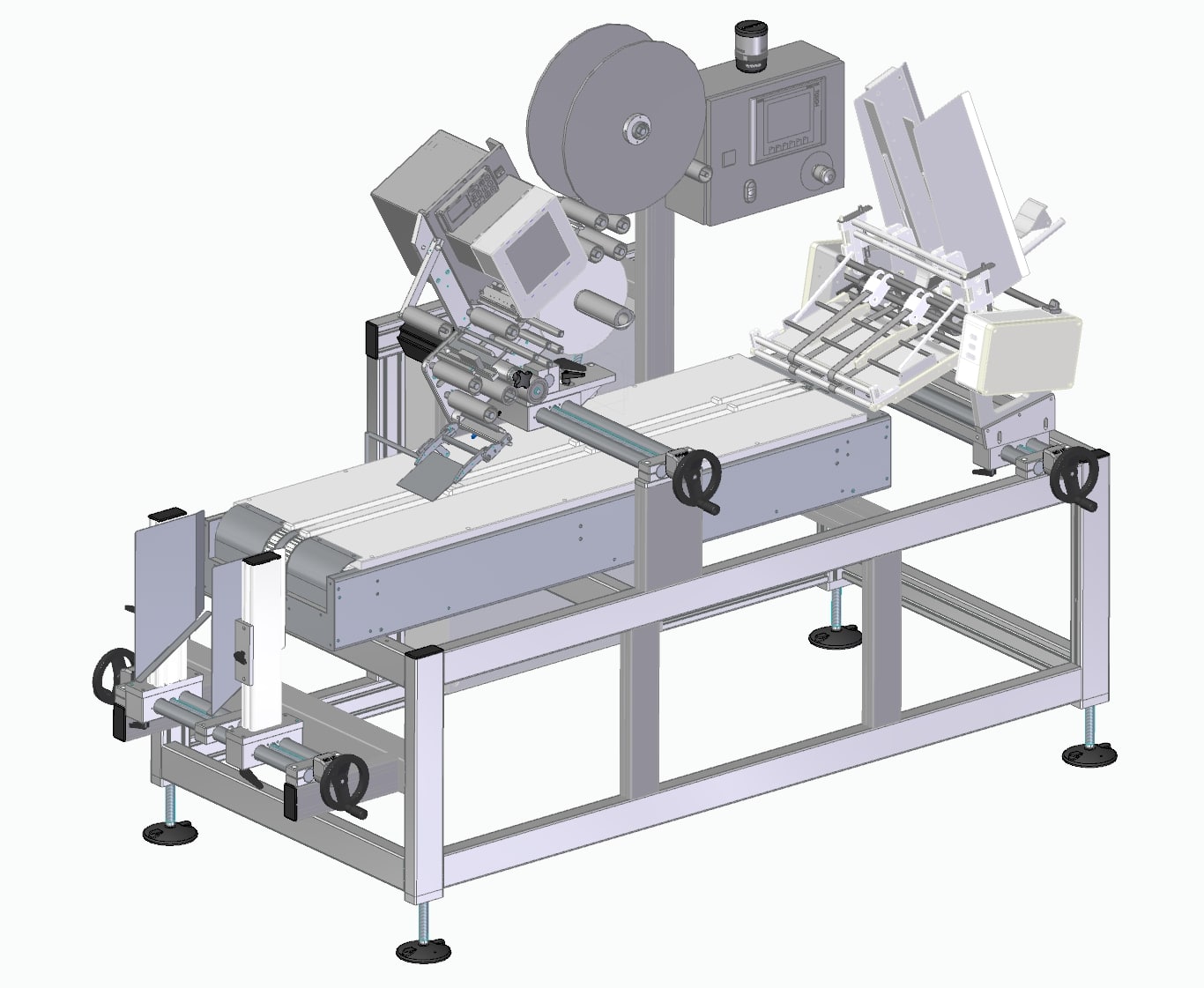

Fully automatic labelling systems

All SES labelling machines are also available as complete labelling systems, consisting of conveyor technology, label dispenser, printing system and, if necessary, other special components. Each system is individually adapted to your requirements and delivered together with the necessary components as a complete labelling system. Thanks to our modular design principle, the systems can be converted to each individual product in a very short time. In addition, you can choose from a wide variety of conveyor technology modules – from belt conveyors to toothed belts to chain conveyor technology. Depending on the production environment, there is the option of manufacturing the main components of the labelling system from stainless steel or aluminium.

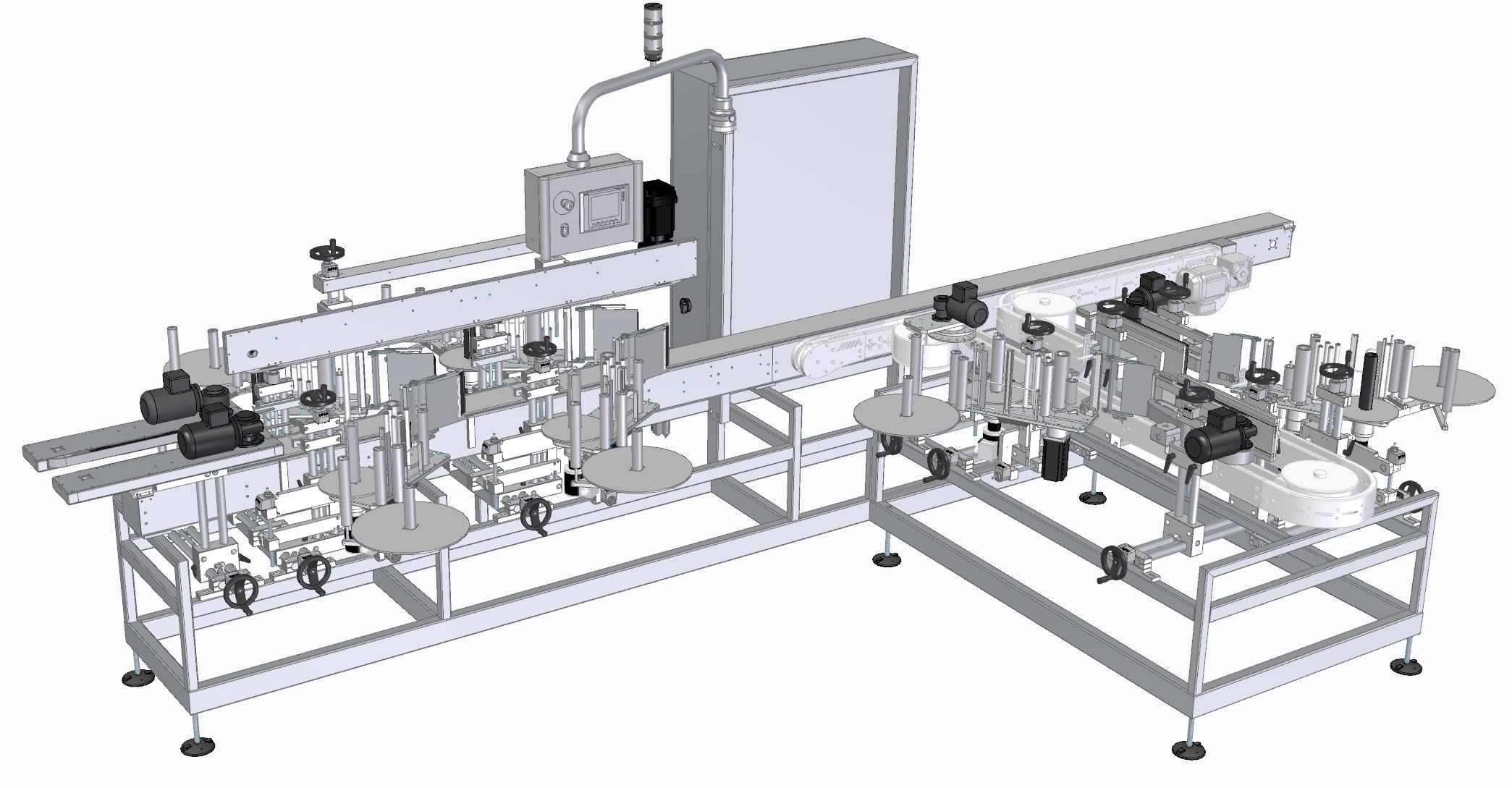

Labelling systems in tandem design

Our high-performance tandem labelling systems ensure a smooth production flow. Thanks to multiple labelling units connected in series, which alternate by means of a highly complex control system in the event of a label shortage or malfunction, an uninterrupted production run is guaranteed at all times. Material changes and troubleshooting can thus be carried out while production continues.

SES tandem labellers are available in various sizes with two to eight labellers and an output of up to 300 labels per minute, with optimum line output. They can label almost all surfaces of the most varied package shapes, as well as over corners as tamper-evident labelling.

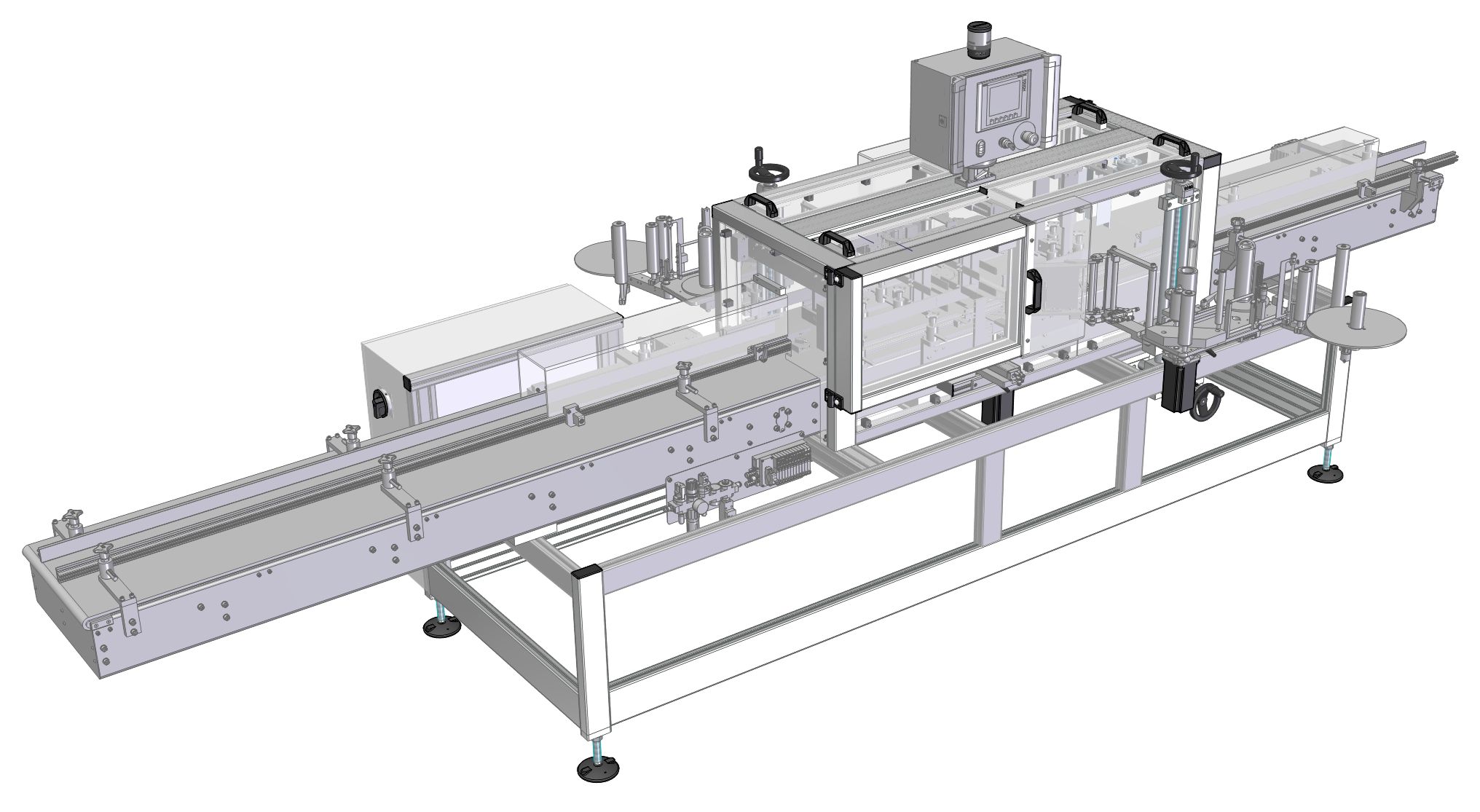

Double-line labelling systems

Our double-line labelling systems are a fully automatic, cost-effective alternative to so-called rotary systems and are ideal for labelling complicated product shapes such as rectangular or oval cans. The products are divided between two labelling lines, so that doubling the line output is possible without any problems.

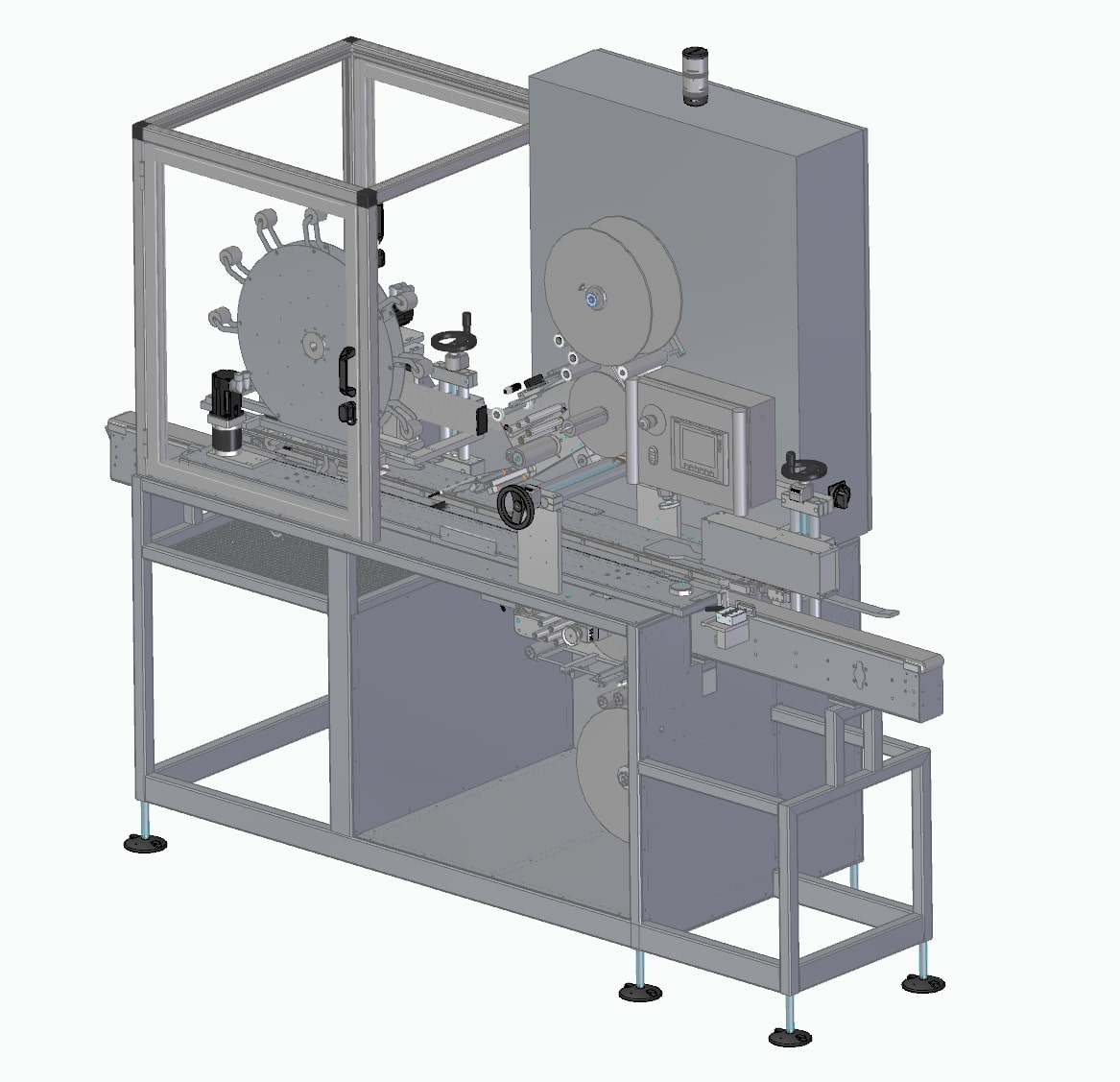

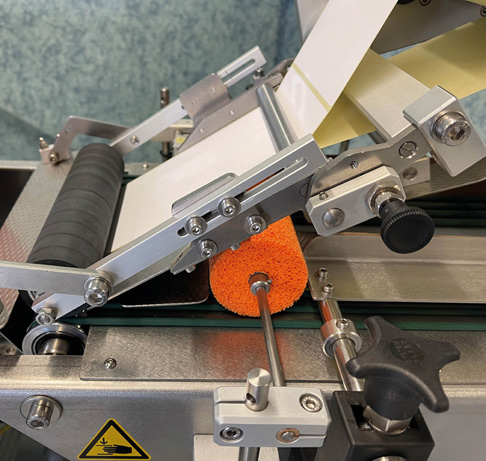

Thermal transfer labelling systems

Cost-effective, environmentally friendly and ideal for customising your labels: with our systems and state-of-the-art thermal transfer printing technology, you can print your labels immediately before applying them to the product. And in the highest quality: thermal transfer printing offers excellent print resolution in 300 or 600 dpi and extremely durable labels. It works on a wide range of materials, such as standard or chrome paper, polyethylene and polypropylene films, textile fabric, as direct printing on products and product packaging.

Our thermal transfer systems can be easily and flexibly installed in your conveyor or production system. Thanks to the modular design principle, different components can also be installed within the systems. The printing systems are available as different models and in different printing widths.

The associated label design software can be perfectly integrated into your IT infrastructure. Via an interface to several common types of databases, you can quickly and easily transfer the existing information to the desired label. All common GHS symbols, for example, are also available as standard.